Behind The Scenes: Three Hidden Water Feature Components (And Why They Are So Important)

From towering water jets to bubbling urban brooks, architectural water features are diverse structures that vary in shape, size, and purpose. Designers and developers work to create projects that capture the imagination and help define and accentuate the spaces they occupy. This practice leads to water features pushing creative boundaries by challenging norms and adapting to advancements within the architectural field.

Although there is a multitude of variables that can influence the appearance of architectural water features, they are still powered by fundamentally similar mechanical systems. Behind the scenes, most fountains, pools, and waterfalls have control rooms full of apparatus that are relatively homogenous. This makes the installation process much less costly in terms of resources and time, and also permits scalability.

These are some of the basic components that power architectural water features:

Pumps:

Pumps are a vital component of the vast majority of water features. They re-circulate water through the features’ network of pipes and fixtures. Regarded as the ‘heart’ of the system, pumps are essential as they continually filter the water, prevent stagnation, and perpetuate the visual effects of jets, waterfalls, fountains, and any other moving part of the feature’s presentation.

High-quality water features use dry-mounted centrifugal pumps. Centrifugal pumps are exclusively used by Vincent Helton and are ideal for commercial use as they are extremely efficient and also boast a lifespan of twenty years or more. They are embedded within the mechanical room and can be accessed and maintained without needing to drain the entire feature.

Pump systems would not be complete without Variable Frequency Drives, otherwise known as VFDs. Although not a mainstay of traditional fountains, VFDs are an integral part of Vincent Helton’s designs. These electrical components control the energy output required to operate the pump, ensuring that it is at a level that meets the designer’s specifications. VFDs reduce the impact of what could otherwise be a serious energy drain. With many cities shifting toward eco-friendly paradigms, optimally running VFDs are more important now than ever.

In addition to the aforementioned parts, all systems are of course supported by a network of pipes, valves, and electrical modules. Their purpose and structure vary with the design of the feature as well as the environment in which it is constructed.

Filtration:

Without some form of filtration, leaves, dirt, and other detritus would plug up outdoor water features very quickly. This is not only an eyesore but can also cause irreparable damage. Within the pond basin, drain covers and strainers are installed to keep large pieces of debris out of the piping system. Inside the mechanical room, basket strainers act as another line of defense, ensuring that no harm is caused to the pump intake. Furthermore, they are connected to the water line directly, allowing technicians to release air from the system as needed.

Algae Control Systems:

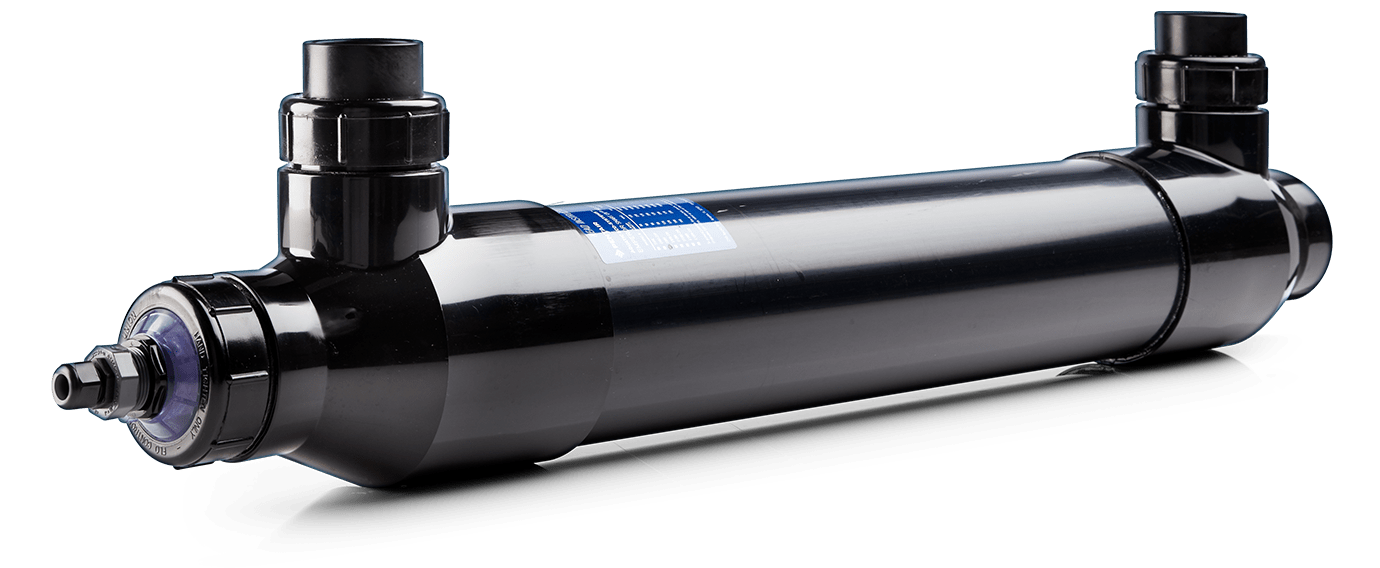

Commercial water features are meant to be experienced by the general public. Because of this, due diligence must be taken to preserve their aesthetic value. Algae is a common type of growth that impacts features in wet climates. It creeps around the edges of the waterline, producing an unsightly ‘scum line’. Since traditional filters do little to eliminate these growths, most architectural water features contain ultraviolet light installations. When water is circulated through this section of the system, it passes by the UV, which purifies and helps remove unwanted growths and bacteria.

It is important to note that failures in the other parts of the filtration system can render the UV’s benefits null – too much residue in the water can severely limit its purifying effects.

Bacterial elimination is reinforced through the use of chlorine feeders. These systems emit chlorine into the water feature at regular intervals, ensuring that the water is purified on a consistent schedule. Features that are intended for direct interaction or ‘water play’ may use a combination of both of these systems so as to guarantee the safety of all. In the right situations, standard bleach and chlorine compounds can expedite the cleaning of algae-ridden features.

Despite their outward complexity, many water features share a basic set of components. Modern features require the elements listed above to preserve longevity, guarantee safety, and preserve energy costs. As the field continues to evolve, so does the efficiency of these parts, which, despite the advancements, still maintain the same basic function.

For more information about these or other water feature components, visit our equipment sales and support website at Pacific Fountain Supply, or Contact Us.